How to choose your industrial casters and wheels?

- The different types of industrial casters and wheels

- Industrial casters from a real professional

- The different selection criteria

The choice of industrial casters and wheels is generally not given great importance. This equipment is essential for the proper functioning of “furniture”, as well as for safety in the workplace.

The different types of industrial casters and wheels

The different types of industrial casters and wheels

Whether furniture or trolleys, they are purchased with industrial casters adapted to their use. But there will come a time when you have to replace them because of wear or because the environment of usage has changed. Right now, how do you choose the right model? First of all, be aware that there are different types of industrial wheels and casters. There are for example different types of the yoke: swivel, fixed without a swivel, and swivel with brake.

The yoke can be fitted with a plate fixing, eye fixing (central hole), or fixing with threaded rod. Also note that the industrial wheel is composed of a rim, a bearing or hub, and a tire. Again, there are roller, ball or plain bearings, and tires with different coatings such as synthetic rubber, pneumatics, and polyurethane. Each material and each production is suitable for a type of use and a particular environment.

Industrial casters from a real professional

You now understand that choosing industrial wheels or casters is not given. And we will then see that there are several criteria to take into account. The technical aspect is not negligible and it is important to call on a professional in the field like the Chinese manufacturer of industrial wheels YTCASTER. A true professional will be able to advise you on choosing the wheels, casters, and mounts suited to your needs. He will have the necessary expertise about the operation of industrial wheels, but also consider the work safety. You can even take advantage of its know-how to train your teams and optimize your work environment.

The different selection criteria

As we mentioned before, there are different criteria to take into account when you want to buy industrial wheels. The main factors are the type of soil on which the wheels will run, the load they will have to carry, the intensity of use and the conditions of the working environment. For this last point, we consider the presence of humidity, aggressive chemicals, or very high temperatures. The type of soil particularly influences the choice of tire, but also the rest of the elements such as the bearing.

Smooth floors, for example, require a hard polyamide or polypropylene bandage to ensure good performance in terms of load capacity. For exterior floors which are generally unpaved or irregular, a pneumatic or elastic rubber tire is preferred. It will also be necessary to take into account the load capacity, the comfort of use, and the degree of noise pollution to name a few characteristics.

With the support of your experienced supplier, you will surely be able to choose the industrial wheels that best suit your performance and safety needs.

Importance of choosing the right industrial casters

It is vitally important that every company bear in mind that both the wheels and the rollers and even the appropriate supports are ideal for the prevention of accidents in the work areas, which is why they must, yes or yes, devote the necessary attention to their correct use in vehicles, as well as on pallet trucks, mobile scaffolding, among others.

If we should be very aware of something, it is that we cannot ignore the fact that choosing the right industrial wheels means guaranteeing the workers’ safety, since in this way accidents at work can be prevented and this is an aspect that every company must take into account, however, this is not the case yet, as there are currently many companies that ignore this important aspect.

At this point, it is vitally important for every company to bear in mind that both wheels and rollers and even the appropriate supports are ideal for the prevention of accidents in work areas, which is why they must, yes, or do devote attention to them. necessary to correct use in vehicles, such as trucks, mobile scaffolds, among others, but in this post, we want to focus today to talk mostly about the importance of choosing the perfect industrial wheels suitable no more than narrow Let’s start fully with this interesting topic.

As we mentioned earlier, being able to choose the right industrial wheels undoubtedly guarantees the own safety of workers within the company, so every company or company should take the time to inquire about which wheels they should choose for their vehicles. or certain machinery, in this case, we must inform you that these are often chosen for each specific use, that is, at this point, several key factors must be considered to choose the appropriate industrial wheels, for example, those mentioned below.

As we mentioned earlier, being able to choose the right industrial wheels undoubtedly guarantees the own safety of workers within the company, so every company or company should take the time to inquire about which wheels they should choose for their vehicles. or certain machinery, in this case, we must inform you that these are often chosen for each specific use, that is, at this point, several key factors must be considered to choose the appropriate industrial wheels, for example, those mentioned below.

Key considerations:

Weight and nature of the load to be transported: every company must know that in this case, they must choose wheels that under no circumstances deteriorate under the applied load, so you must then calculate the load capacity of the wheels depending solely on the weight of the cargo that is frequently transported in company vehicles.

Type of displacement: at this point, it is important to explain, that if the displacement is mainly manual, you will have to choose some industrial wheels with excellent characteristics of displacement happiness, the same ones that generally can reduce the effort to, On the other hand, if the displacement also involves traction, they should always choose products that are highly resistant to shocks and that can also easily withstand displacement at high speeds, thus preventing unnecessary future accidents.

The characteristics of the route: this is another factor to take into account to choose the right wheels since a rectilinear route or one with various changes of direction requires different options in the configuration of wheels plus support.

Soil: if the soil is banished, uneven or it presents many obstacles along the way, you will need wheels with an elastic bandage, in the case of smooth and regular floors you can without any problem be associated with the use of wheels with the harder band, since they usually offer better benefits in terms of load capacity, which is great in this case.

The environment: if the place is frequently humidor there are aggressive chemical substances, it is vitally important to make products made with super resistant materials, such as choosing wheels made of plastic materials with stainless steel supports.

Industrial casters: buying guide

The minimum composition of an industrial caster includes a wheel, a fixed or swivel mount, an axle, and a bearing system. There are 4 main types of industrial casters: fixed and swivel with plates, swivel with rod and swivel with a central hole.

How to choose the best industrial roulette tire?

The two main elements that determine the quality of a caster are on the one hand the type of tire and on the other hand the type of rolling. The material of the tread (the tire) is of paramount importance in the choice of the wheel or the caster.

The 5 main criteria for choosing the type of tire.

1. Load capacity sought (weight of the load to be transported + weight of the handling device).

2. Type of soil.

3. Efforts at start-up and rolling desired (pushing force required to start and move a rolling load).

4. Ease and comfort of use (ease of rolling, noise …).

5. Desired travel speed (<4 km / h = manual use or> 4 km / h = mechanical traction).

- Load capacity – Maximum load supported by a wheel. The load per wheel is equal to the sum of the weight of the truck and the load to be transported divided by the number of wheels in permanent contact with the ground – i.e. the total load divided by 3 to 4 km / h, at an ambient temperature included between 10 ° and 30 ° C, on even ground.

- Start-up effort – Force required to move the caster from a stationary position to a state of movement. Take this into account when using the devices by women.

- Rolling resistance – Force required to keep the caster in its moving state.

- Resistance to tire wear – Resistance of the tire to mechanical wear over time. It depends on the intensity of use (number of km), the type of soil, the presence of cutting, or aggressive agents on the ground.

- Maneuverability on uneven or uneven ground – Is optimized by the suitability of the type of tire on the wheel about the nature of the ground.

- Comfort and ease of use – Are obtained by the low resistance to starting and rolling and by the absence of noise during use.

- Shock and vibration absorption – Depends directly on the hardness (shore) of the tire.

- Resistance to aggressive agents – Depends on the type of chemicals. It concerns the resistance of the tire and the wheel center as well as the yoke and the fixing plate.

- Temperature resistance – The temperature to take into account for the bandage is room temperature. The resistance of the bandages decreases at high temperatures.

- Degree of noise pollution – Depends on the nature and hardness of the tire and the nature of the ground.

- Conservation and protection of floors – Important criterion on fragile floors such as tiled floors or parquet floors.

- Marking of floors – There are solid or pneumatic rubber castors in a “non-marking” version in gray or black color intended to avoid marking fragile floors.

Solid rubber semi-elastic |

Synthetic rubber |

Solid, super-elastic rubber |

Polyamide Nylon® |

Pneumatic |

Polyurethane injected |

|

|---|---|---|---|---|---|---|

| Charge capacity | Good | Good | Very good | Very good | Low | Very good |

| Example load capacity diam. 200 mm | 200 kg | 200 kg | 300 kg | 250 kg | 75 kg | 250 kg |

| Effort to be made at start-up | Important | Way | Low | Very weak | Very important | Very weak |

| Rolling resistance of the carriage | Low | Low | Very weak | Very weak | Strong | Very weak |

| Maneuverability on uneven and uneven ground | Good | Good | Very good | Bad | Very good | Very good |

| Comfort and ease of use | Well | Well | Very good | Way | Very good | Very good |

| Shock and vibration absorption | Good | Average | Very good | Bad | Very good | Good |

| Resistance to tire wear | Average | Average | Good | Very good | Average | Very good |

| Resistance to oils, greases and acids | Very average | Very average | Average | Big | Very average | Very good |

| Extreme temperature use | -30 ° to + 80 ° C | -30 ° to + 80 ° C | -30 ° to + 80 ° C | -20 ° to + 80 ° C | -30 ° to + 80 ° C | -30 ° to + 80 ° C |

| Noise | Quiet | Quiet | Very silent | Very noisy | Very silent | Quiet |

| Soil conservation and protection | Average | Average | Very good | Very good | Very good | Very good |

| Marking and soil tasks | Staining | Not staining | Not staining | Not staining | Staining | Not staining |

| Unbreakable yes / no | no | no | Yes | Yes | no | Yes |

Professionally Caster Wheel Manufacturer In China

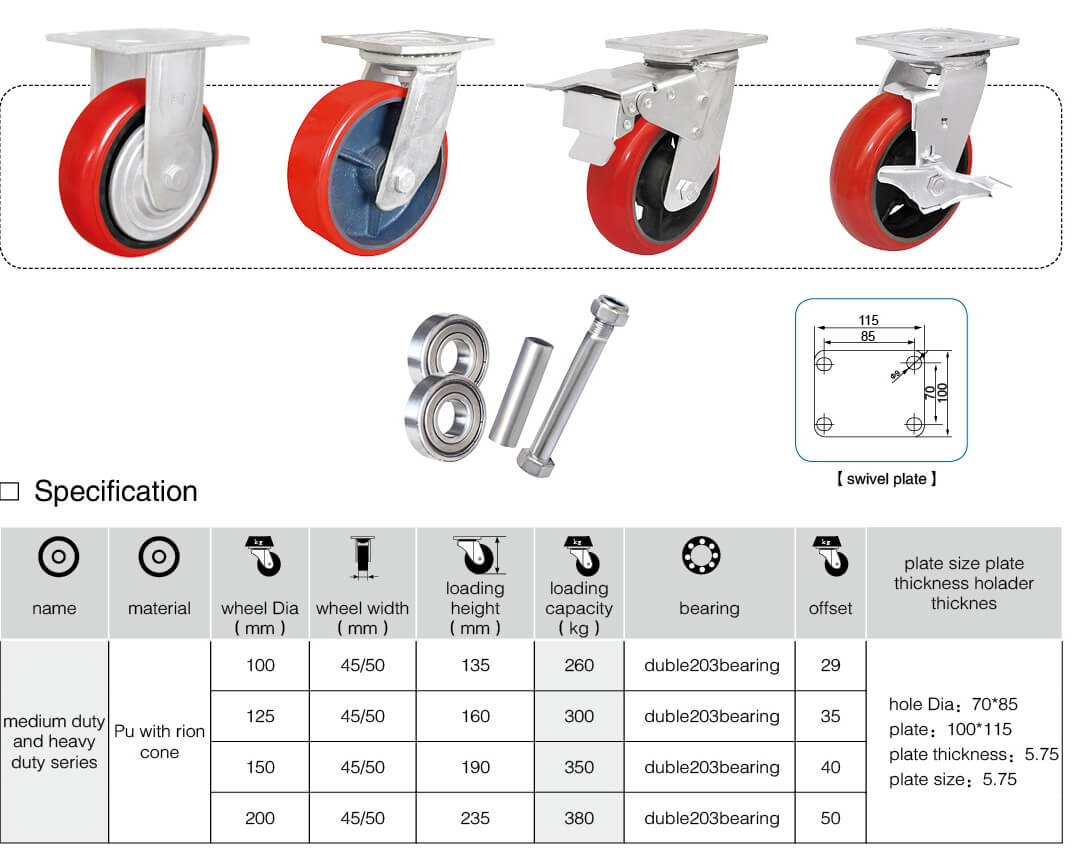

Our products include Industrial Casters, Heavy Duty Casters, Scaffolding Casters, and Shock Absorbing Caster Wheel. Wheel materials include rubber caster wheel, steel caster wheel, plastic caster wheel, iron caster wheel, polyurethane caster wheel, nylon caster wheel, cast iron caster wheel, and so on. The caster bracket has swivel caster wheel, fixed caster wheel, caster wheel with lock, caster wheel with double brake , and caster wheel with side brake.

Our website shows most of the industrial casters we produce. These are our most popular caster wheel. If you don’t find the products you need, please contact us or send us email. Our experienced staff will be happy to help you.

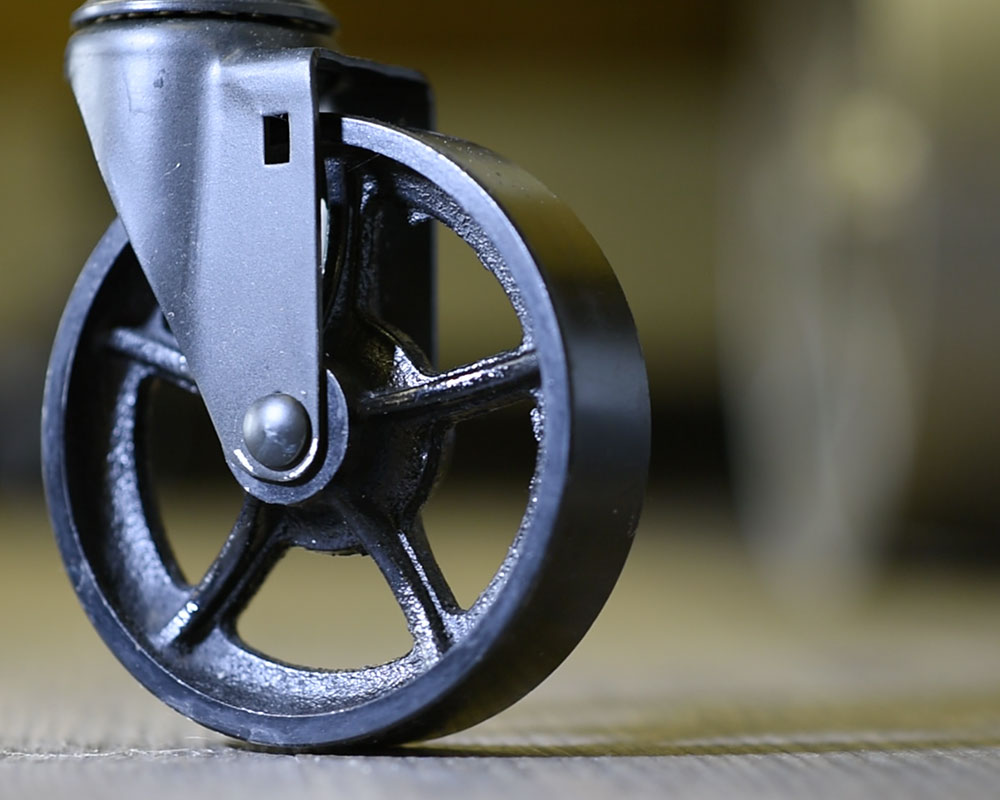

INDUSTRIAL 6 INCH CAST IRON CORE PU RIGID/FIXED CASTER WHEEL SERIES

Maneuverability, positioning, and types of industrial casters for carts

The industrial casters for handling trolleys or roll-containers must be positioned according to the maneuverability criteria of the trolleys or handling devices. There are many combinations and types of wheel positioning. We have listed 6 main ones, each presenting advantages but also disadvantages in relation to the use of the carriages on which the rollers are mounted.

2 fixed casters + 2 swivel casters

2 swivel at the push handle – 2 fixed at the front

This is the most frequently used combination and positioning of industrial casters. Ideal for both straight line use and curve use. This combination presents a certain difficulty of use in narrow aisles.

4 swivel casters

Has the advantage of extreme maneuverability. Ideal for narrow aisles. The disadvantage of the combination is the difficulty of directing the carriage in a straight line “mad carriage”. Mounting a directional lock on at least one of the swivel casters considerably improves guidance.

4 swivel casters, 2 of which have brakes at the push handle.

Has the advantage of extreme handling. Ideal for narrow aisles. The disadvantage of combination is the difficulty of directing the carriage in a straight line “mad carriage”. The brake ensures the safety of the truck and its load, especially on inclined floors.

4 swivel casters, 1 of which with directional locking

Combines the advantage of extreme maneuverability in tight spaces and narrow aisles with the possibility of locking the steering for driving over long straight distances. Mounting a directional lock on one of the swivel casters considerably improves guidance. Ideal for uses requiring great maneuverability.

These kings of industrial casters can all found in YUTONG CASTER–Professionally Caster Wheel Manufacturer In China.