The market offers a wide variety of industrial wheels for moving machines and trucks in all sectors. Their characteristics that make them more or less suitable for different applications and environments.

Based on these and other parameters, companies can choose the most suitable industrial wheels for their vehicles to obtain maximum efficiency and operator safety in the long term.

To obtain maximum vehicle efficiency, what characteristics should the wheels have?

4 FACTORS TO CONSIDER WHEN CHOOSING INDUSTRIAL WHEELS

A number of aspects need to be evaluated, from ease of movement to safety of the truck or machine.

A number of aspects need to be evaluated, from ease of movement to safety of the truck or machine.

Here are the 4 key factors to consider when choosing wheels :

1. Nature and conditions of the paving: that is, the base on which the truck will move;

2. Environment : take into account the possible presence of aggressive chemical products and humidity levels and temperatures, normal or extreme;

3. Magnitude and nature of the load : we refer specifically to the total weight that the truck must support, the nature of the load (solid or liquid) and the calibration of the truck. All these elements determine the minimum capacity of the wheel of the truck to guarantee a safe movement;

4. Traction and speed vehicles : depending on the type of movement (which can be manual or mechanical) and the speed of the truck, certain types of wheels must be chosen, discarding those that are not suitable for certain objectives.

The ideal choice in terms of costs will be the one that best meets the specific requirements of use.

THE TECHNOLOGY APPLIED TO THE INDUSTRIAL WHEELS SECTOR

Technology is the basis of the company’s growth and competitiveness. The industrial wheels sector is no exception, where innovation constantly leads to the creation of ever-higher performance models.

Technology is the basis of the company’s growth and competitiveness. The industrial wheels sector is no exception, where innovation constantly leads to the creation of ever-higher performance models.

Without any doubt, Yutong strictly follows these principles since it began to produce wheels and supports for industrial, civil, and domestic use. Today the production is carried out in the 3 Formigine plants on a covered area of 15,000 ㎡.

Each manufacturing phase is using product quality and the use of qualified skills, up-to-date technologies and modern software to distinguish. It will guarantee complete customer satisfaction.

THE MOST INNOVATIVE AND TECHNOLOGICALLY ADVANCED WHEEL MODELS

Investments in research and development have allowed Yutong to design new products, studied by the accredited in-house laboratory TR Lab Test & Research based on market demands, and to distinguish itself from most domestic and foreign competitors.

Investments in research and development have allowed Yutong to design new products, studied by the accredited in-house laboratory TR Lab Test & Research based on market demands, and to distinguish itself from most domestic and foreign competitors.

We will now list several examples of wheels and supports for industrial use derived from advanced technological processes.

- Sheet steel supports and combination wheels

- Stainless steel supports resistant to humidity and aggressive chemicals

- Plastic wheels

- Polyurethane and Vulkollan® wheels

- Custom polyurethane wheels

- Antistatic and conductive wheels

- Anti-fingerprint wheels for delicate floors

Read each solution to discover its technical characteristics and peculiarities.

SHEET STEEL SUPPORTS AND COMBINATION INDUSTRIAL WHEELS

Concerning industrial wheels, brackets are critical for the characteristics and performance of trucks and other types of products.

The support is the connecting element between the wheel and the truck. Normally, all wheels require the use of a bracket to be applied to the truck or equipment. The integration of wheels with axles in trucks is an exception.

Let’s start with the supports and components of sheet steel made with automatic mechanical presses for high tonnage step molds.

The Yutong range for this type of substrates is briefly described below, meeting many demands of industrial paving.It is always recommended to evaluate the load capacity of the Wheel and support assembly, which is limited by the weakest element of the combination. For example, if the wheel has a capacity of 500 kg and is mounted with a support of a capacity of 300 kg, the wheel and support set will have a capacity of 300 kg.

SL supports:

For light loads (up to 130 kg) and infrequent manual movement.

Combination with standard and thermoplastic rubber wheels.

NL supports:

For light and medium loads (up to 300 kg) and manual movement, even frequent.

Combination with resin wheels and all Yutong wheels.

A specific version is available for use at high temperatures.

M supports:

For medium loads (up to 500 kg) and manual movement, even intense.

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels, thermoplastic polyurethane wheels, polyamide wheels.

P supports:

For heavy loads (up to 750 kg).

Intense manual and mechanical displacement.

mixed manual-mechanical with maximum speed up to 6 km / h.

low frequency of displacement.

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels, thermoplastic polyurethane wheels, polyamide wheels.

PT supports:

For heavy loads (up to 850 kg),

Intense manual and mechanical displacement

Mixed manual-mechanical with maximum speed up to 6 km / h

Frequency of movement still very high.

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels.

EP supports:

For very heavy loads (up to 1000 kg)

Intense manual and mechanical displacement

Mixed manual-mechanical with maximum speed up to 8 km / h

High frequency of displacement.

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels.

EE MHD, EEG MHD, EE HD, EEG HD, EE EHD models: welded and twin

Welded supports:

For application with very heavy loads (up to 3500 kg).

High speeds of use (up to 16 km / h).

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels.

Electro-welded supports with spring models EES MHD:

Designed for use in trucks with guaranteed displacement by mechanized trailer.

With speeds of up to 16 km / h.

For interior and exterior transport.

In the presence of obstacles or irregular pavements.

Combination with TR and TR-Roll polyurethane wheels, Vulkollan ® wheels, elastic rubber wheels.

STAINLESS STEEL SUPPORTS RESISTANT TO HUMIDITY AND AGGRESSIVE CHEMICALS

Yutong also proposes a complete range of stainless steel supports studied to meet specific customer requirements, with characteristics of resistance to humidity and aggressive chemicals, and solutions for the food and chemical industry and, more generally, for situations that provide for frequent washing and sterilization during the production process.

Yutong also proposes a complete range of stainless steel supports studied to meet specific customer requirements, with characteristics of resistance to humidity and aggressive chemicals, and solutions for the food and chemical industry and, more generally, for situations that provide for frequent washing and sterilization during the production process.

NLX supports:

For light and medium loads (up to 300 kg) and manual movement, even intensive.

A specific version is available for use at high temperatures.

Combination with resin wheels.

PX supports:

For heavy loads (up to 750 kg)

Intense manual and mechanical displacement

Mixed manual-mechanical with maximum speed up to 6 km / h

Low frequency of displacement.

Combination with plastic wheels, suitable for use in the presence of humidity and aggressive chemicals.

PLASTIC INDUSTRIAL WHEELS

Without leaving the subject of innovation, a brief clarification on the different models of plastic wheels. In this case we are talking about polyamide (nylon), polypropylene, thermoplastic rubber, and thermoplastic polyurethane wheels. Fully automated injection mechanism makes all these models.

Without leaving the subject of innovation, a brief clarification on the different models of plastic wheels. In this case we are talking about polyamide (nylon), polypropylene, thermoplastic rubber, and thermoplastic polyurethane wheels. Fully automated injection mechanism makes all these models.

The high automation of the processes allows the thermoplastic and polyamide polyurethane wheels made by Yutong to guarantee high performance at a competitive price.

POLYURETHANE AND VULKOLLAN® WHEELS

The production process of the wheels with polyurethane coating, devised and designed by Yutong, is completely automatic and guarantees complete control of all phases: preparation of the cores, preparation of the different polyurethane formulations, casting and setting.

The TR and TR-Roll polyurethane wheels are made with formulations studied in the TR Lab – Test & Research laboratory to guarantee the best value for money and excellent performance according to different application requirements.

Under the Covestro license, the company produced the wheel Vulkollan®, which has strict production specifications to meet the most demanding application conditions in terms of weight, load and speed.

CUSTOM POLYURETHANE WHEELS

Technology today enables an increasingly high degree of customization, even in the field of industrial wheels.

Yutong proposes customized products with polyurethane coating made by modern dedicated lines, in which expert operators take care of every detail required by customers, guaranteeing quality and performance.

The research and development laboratory TR Lab has developed polyurethane formulations that respond to different demands, such as reduced thrust effort, reduced vibrations and noise, minimal maintenance, specific electrical conductivity, and several other advantages, calibrated according to the needs of each company.

ANTI-STATIC AND CONDUCTIVE WHEELS

SAFETY FOR SENSITIVE ESD ENVIRONMENTS

The plastic material, rubber, and elastomers used in the industrial wheel sector are generally insulating and do not conduct electrical charges.

The plastic material, rubber, and elastomers used in the industrial wheel sector are generally insulating and do not conduct electrical charges.

The use of these materials does not allow the dispersion of charge to the ground during the use of the accumulated charge on the wheels of machines or trucks.

The accumulation of electrical charges can lead to the generation of discharges that can compromise the operation of electrically sensitive material transported in the truck/machine and trigger explosive phenomena in hazardous environments.

Wheels made from these materials may be unsuitable for potentially explosive environments and environments sensitive to electrostatic discharge.

(Sensitive ESD).

Yutong proposes customized wheel solutions for sensitive ESD environments with modified electrical characteristics, which respond to electrical conductivity requirements to various degrees:

Black rubber wheels with R <10 5 OHM (“conductive” according to ISO 22883: 2004).

Polyamide 6 wheels with R <10 5 OHM (“conductive” according to ISO 22883: 2004).

Polyurethane wheels with R <10 9 OHM

At the request of the customer, the wheels with TR polyurethane coating and TR-Roll polyurethane (series 62AL, 62ER, 62GH, 64, 65AL, 65GH, 65HT, 65ER) can be made with a suitably modified polyurethane coating to obtain resistance characteristics electrical <10 9 Ohms.

ANTI-FINGERPRINT WHEELS FOR DELICATE FLOORS

Today, delicate pavements are also made in industrial settings. These pavements need to be kept protected and clean over time. This is usually the case in environments with high hygiene needs, such as the food and pharmaceutical industries.

In these contexts, it is essential to use wheelbarrows that do not stain or mark the pavement.

Yutong proposes anti-fingerprint and anti-stain wheel solutions for different types of industrial uses:

- Light loads: standard rubber and thermoplastic gray wheels.

- Medium loads: thermoplastic polyurethane wheels and blue anti-fingerprint elastic rubber.

- Heavy loads and mechanical displacement: TR-Roll polyurethane wheels.

- High temperatures: anti-stain silicone rubber wheels.

LEAN PRODUCTION METHOD AT CUSTOMER SERVICE

Yutong’s production processes are organized according to the principles of Lean production, aiming to minimize waste and at the same time guarantee the customer punctual delivery times thanks to the flexibility of the service.

Yutong’s production processes are organized according to the principles of Lean production, aiming to minimize waste and at the same time guarantee the customer punctual delivery times thanks to the flexibility of the service.

The combination of Lean production and traceability at every step through the management information system offers customers a high degree of flexibility in terms of production quantity and product and packaging marking, without affecting the speed of deliveries.

There are many excellent caster suppliers, like Yutong in China, which offers advantages like quality, service, and price. Hengshui Yutong Metalwork Co., Ltd. is a China wheel manufacturer with nearly 20 years of professional experience. With its superb technology, high-quality products, and perfect after-sales service, it has won the trust of customers. Yutong specializes in the production and export of industrial casters of various specifications. It can provide customers with free samples for testing, and it can deliver 3-4 days before other businesses in the industry. At the same time, the company provides OEM and ODM services to serve customers worldwide.

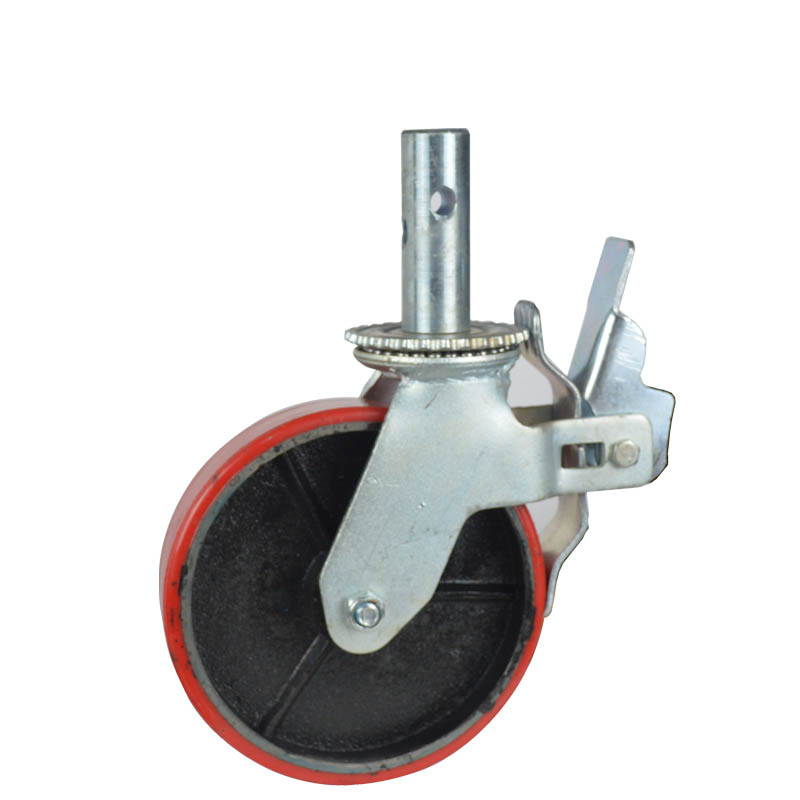

We recommend the terrific industrial caster wheels:

With Locking Brake: Each wheel has a separate brake. In fact, the brake locks both the wheel and the swivel simultaneously. In other words, effectively to stop and prevent the device from moving and hurting others.

With Locking Brake: Each wheel has a separate brake. In fact, the brake locks both the wheel and the swivel simultaneously. In other words, effectively to stop and prevent the device from moving and hurting others.

360 Degree Rotation Top Plate: Easy to transform to any directions that you want, and spend little strength to move on.

PP Core With PU Wheel, Wear-Resistance, Durable Quality. Quiet and no noise when moving, don’t worry to disturb your family or others. Safe for all floor types.

Widely Used: Can be used in both industrial and residential applications, for industrial trolley, heavy duty equipment, lightweight mobile platform, coffee table, plant stands, bookshelves, shoe bins, toy bins, underbed storage, shopping carts, workbench.